About Us

Worn Again has a unique, trail-blazing heritage.

Worn Again was founded to drive the adoption of a circular economy.

We strive to transform current textile recycling systems with scalable chemical technologies.

To accelerate our impact, technology licenses are available to operators that share our vision.

CHEMISTRY

IN THE

MAKING

2005

Founding date

Worn Again enters the textile upcycling market, reverse manufacturing used textiles back into new products

2012

Transitioning to chemical solutions for textile waste

As a leading innovator in circularity, Worn Again tests dissolution of textiles at laboratory scale.

2013

Investment from H&M, pivot to technology

To accelerate the adoption of chemical recycling, supported by H&M and Kering, the company pivots to focus on technology development

2017

Investment from Sulzer

Following a successful industrial trial of key separation technology, Sulzer joins forces with Worn Again.

2019

First pilot plant

Start-up of a pilot plant validates the technology. The pilot plant is capable of processing 5kg batches of textiles, a 100x increase from lab scale.

2020

Investment from Oerlikon

Confident in the technology, Oerlikon comes on board. A joint team of Sulzer, Oerlikon & Worn Again start engineering and scale up

2022

Funding secured for a demo plant

With plans for an industrial demonstration plant in Winterthur, Switzerland, Worn Again announces its largest ever funding round and builds a local team

2024

Start up of the demo plant

The plant will prevent up to 1000 tonnes of textiles from being incinerated every year, a 1000x increase from pilot scale. Demonstrations pave the way for industrial-scale operations.

2027

Start up of a first commercial plant

Commercial plants will each convert up to 50000 tons of used textiles into polyester and cellulose for use within a new circular supply chain

TECHNOLOGY

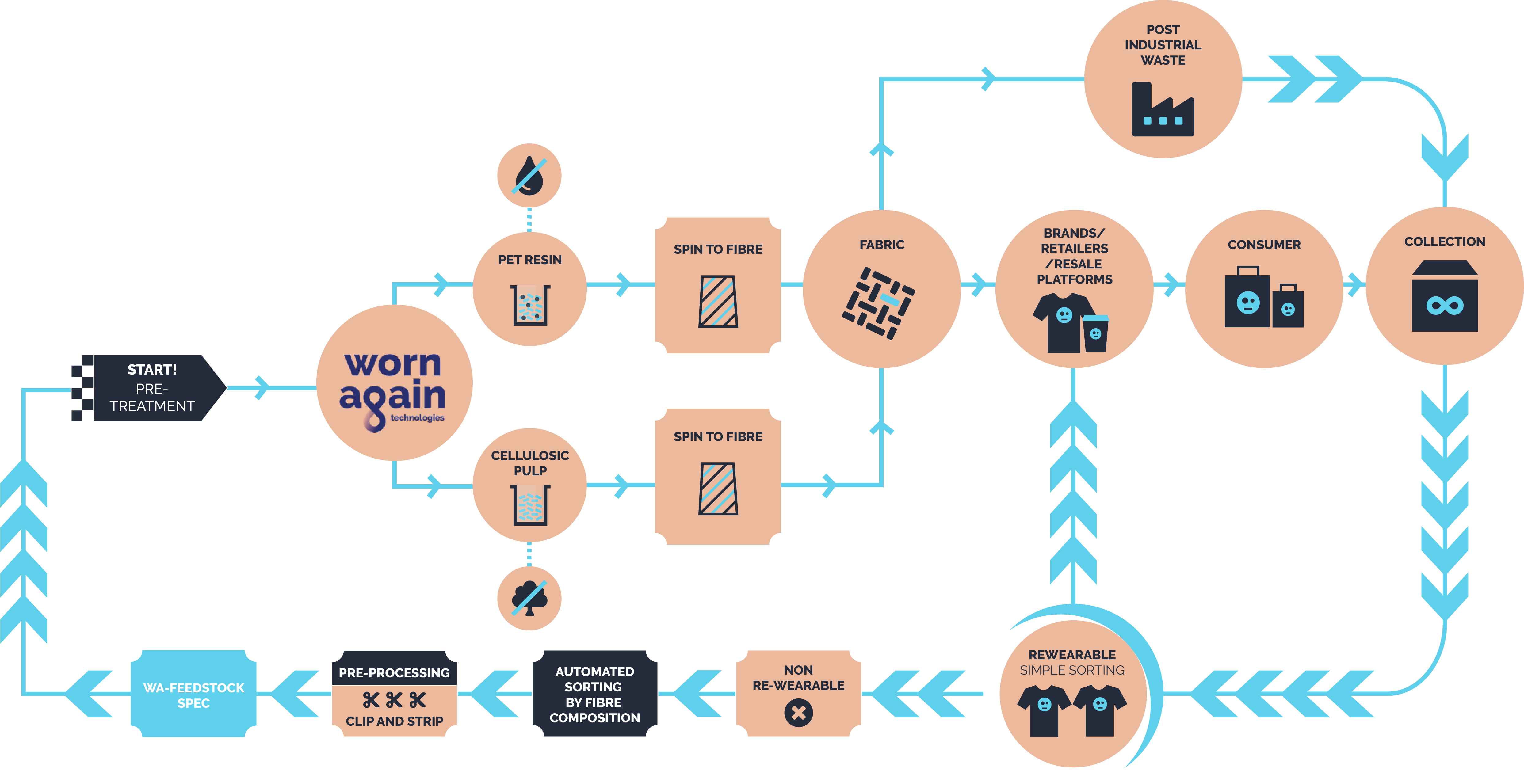

The Worn Again process is the missing link between textiles and a sustainable future. Our dual-input/dual-output approach is a game-changing solution which serves an untapped market. Using special chemicals we clean, extract, separate, and regenerate virgin quality polyester and cellulose. At scale, this eliminates fossil fuel extraction and the destruction of natural resources.

Here is where the technology fits into a fully circular value chain >>

Chemicals for Circularity

Our technology gives operators a superpower – flexibility to process dynamic blends of polyester and cotton textiles.

Closing-the-Loop

Once the chemicals have done their job, we recapture and regenerate them. This ensures optimal chemical utilisation and enhanced environmental benefits.

Circular Raw Materials

Virgin-equivalent, circular materials are ready for immediate spinning to new fibres, polyester and man-made cellulosics. These products unlock the fibre-to-fibre value chain.

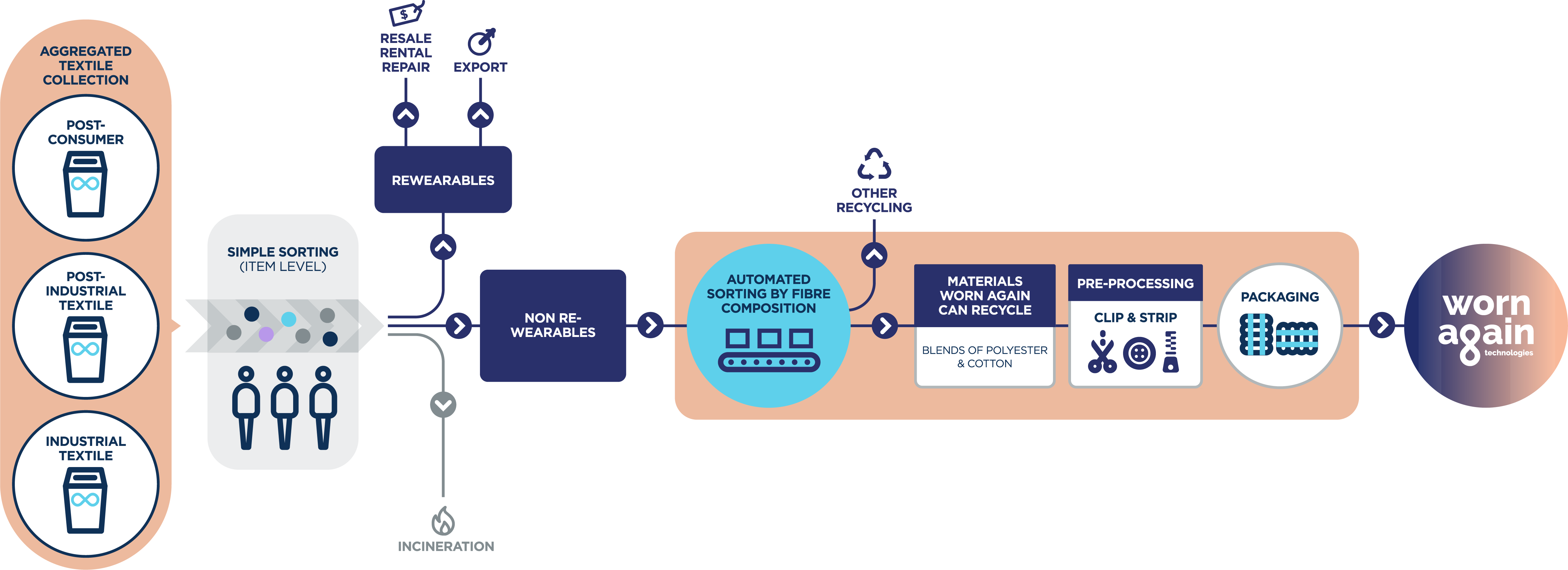

Feedstock development

Worn Again unlocks new life for post-use textile resources. The feedstock supply chain contains several important steps. First, textiles are collected and sorted for Reuse. Responsible Reuse is an important characteristic of the circular economy. However, ultimately, textiles will become Non-rewearable and then they are sorted for Recycling. Using an automated sorting machine, Polyester and Cotton materials can be separated. Finally, the pre-processing step will remove disrupters (such as buttons or zippers) and downsize the material to Worn Again’s requirement.

Reclaim infinity

AND FIND OUT MORE

A waste-free, circular resource world is within reach!

© Worn Again Technologies is a limited company registered in England and Wales. Registered number: 06816793. Registered office: Fieldfisher, Riverbank House, 2 Swan Lane, EC4R 3BF. Website crafted by Pavlina Jankotova.